How to minimize heat loss in a greenhouse in winter? Energy efficient greenhouse

Winter cultivation in Ukraine is a battle not so much for the crop, but for heat. The main cost item of any winter greenhouse (up to 70% budget) is heating. Many beginning farmers try to solve the problem by installing a more powerful boiler, which is a strategic mistake. Warming the street is an unacceptable luxury.

The engineer's task is not to increase the heat inflow, but to block the heat leakage channels. This article is a detailed technical audit of the greenhouse thermal circuit. We will analyze the physics of heat loss, DSTU norms and specific engineering solutions that will reduce heating costs by 2-3 times and make an energy efficient greenhouse.

The physics of cold: Where does the heat go?

Before you can fight cold corners, you need to understand exactly how the greenhouse loses energy. Many people think that heat only escapes "through holes", but the process is actually much more complicated. There are three physical channels through which cold gets in.

1. thermal conductivity (Transmission losses)

This is a direct transfer of heat through the material of the walls, roof and foundation. The higher the thermal conductivity of the material, the faster it "pumps" heat outside.

- Walls and roof: Conventional polyethylene film or glass have a very low thermal resistance. They equalize the temperature inside and outside almost instantly. Cellular polycarbonate works better due to the air in the cells, but its efficiency is directly related to its thickness.

- Primer: In winter and early spring, the ground is a huge refrigerator. If the foundation is not insulated, the heat from the fertile layer escapes into the cold mainland soil and the concrete basement.

Fact: Up to 50-60% of total heat escapes through the greenhouse covering and another 10-15% through the cold ground.

2. Convection and Infiltration (Draft Effect)

Even in the most seemingly airtight greenhouse, there is air movement.

- Infiltration: This is the passage of cold air through micro-slits in the joints of sheets, shutters and doors. If there is a 5 m/s wind outside, then through a gap only 2 mm wide, the greenhouse can lose all the heated air in 30-40 minutes.

- Heat head: The warm air tends upward and seeks an exit under the ridge, creating a rarefaction below. This literally sucks in cold air from the street through the lower gaps in the foundation.

3. infrared radiation (Radiation cooling)

The most insidious enemy that 90% gardeners forget about. During the day, the sun heats the soil and plants (short-wave radiation). At night, heated objects begin to give heat back in the form of long infrared waves.

- Materials Problem: Glass traps IR radiation (the greenhouse effect works). But ordinary polyethylene film is almost transparent to thermal radiation - heat escapes through it like water through a sieve.

- Clear nights: In cloudy weather, the clouds act as a blanket, returning some of the heat. On a clear starry night, radiation losses are maximum - the temperature in the greenhouse can drop lower than outside (radiation frost).

Heat loss table and control methods

| Loss channel | % of total losses | Physical meaning | How to eliminate (Materials in Ukraine) |

|---|---|---|---|

| Coverage (Walls/roof) | 45-60% | Direct heat transfer | Use multi-chambered polycarbonate (6-10 mm) instead of film/glass. |

| Slits (Infiltration) | 25-30% | Blowing warm air | Joint sealing (butyl rubber), rubber seals on doors. |

| Soil | 10-15% | Heat escaping into the ground | Foundation insulation with extruded polystyrene foam (XPS). |

| Radiation (IR) | 10-20% | Radiant heat transfer | Polycarbonate with a special "Bio" layer or additives that block the output of IR rays. |

Engineer's Conclusion: It is impossible to make a thermos greenhouse without windows and doors. But our goal is to increase the thermal resistance (R) of the building envelope and to close off the channels of "rapid heat release" (gaps and cold bridges).

Foundation and Soil: Blocking the cold from below

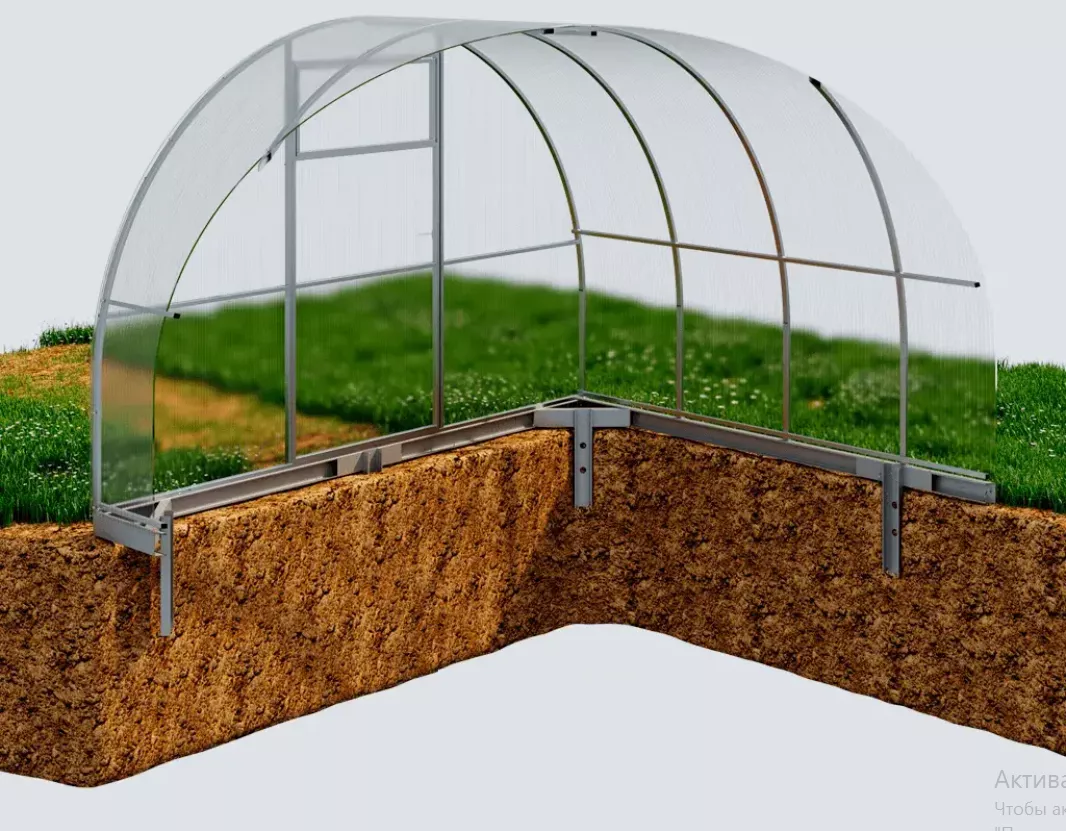

The most common mistake is to place a winter greenhouse simply on the ground or on a cold concrete strip foundation. The ground freezes in winter. In Ukraine, the freezing depth varies from 0.8 m (south) to 1.2 m (north/east) according to DSTU-N B B.1.1.1-27:2010. Without insulation, the foundation acts as a giant cold bridge, siphoning heat from the soil inside the greenhouse.

1. Physics of the process: Why soil is the main enemy of heat

In building thermal physics there is a concept "Zero isotherm.". This is the conditional line in the ground where the temperature crosses 0°C.

- No insulation: In winter, the zero isotherm penetrates under the greenhouse foundation. Concrete foundations have a high thermal conductivity (they transmit temperature perfectly). If concrete stands on frozen ground, it itself becomes an ice radiator with an area of tens of square meters, cooling the air inside the greenhouse from below.

- Frost heaving: There is always moisture in the ground. When water freezes, it expands by 9-10%. If the ground under the foundation freezes, it will literally "bulge", which will lead to cracks in the foundation and distortion of the greenhouse frame (glass or polycarbonate may burst).

2. Material comparison: Why XPS?

Many people try to save money by laying plain white expanded polystyrene (EPS) or expanded clay. Engineering analysis shows why this is a mistake when working in the ground.

The main enemy of insulation in the ground is water. Wet insulation ceases to be insulation (water conducts heat 25 times better than air).

Table of comparative characteristics of foundation materials

| Characteristic | Concrete (Foundation) | Mineral wool | Styrofoam (EPS/PSB) | XPS (Extruded polystyrene foam) |

|---|---|---|---|---|

| Structure | Monolith | Fibers | Balls glued together | Solid closed cell structure |

| Thermal conductivity (V/m-K)* | 1.5 - 2.0 (Very High) | 0.040 (Dry) | 0.038 – 0.042 | 0.029 - 0.032 (Lowest) |

| Moisture absorption (for 30 days) | Actively absorbs | > 100% (gets wet instantly) | 2% - 4% (Absorbs in the gaps between the balls) | < 0.4% (Practically zero). |

| Behavior in the ground | Freezing, destroyed by freezing cycles | Rotting, shrinking, losing properties | Gains water over time, when freezing, the balls break apart | Does not rot, not afraid of water, 50+ years of service life |

| Compressive strength | Huge | Low (crumpled by the ground) | Medium (10-15 tons/m²) | High (25-50 tons/m²) |

*The lower the thermal conductivity figure, the better the material retains heat.

Conclusion: Only closed cell materials can be buried in the ground. Ordinary foam plastic (with balls) in the ground gains moisture through micro pores between the granules. In winter this moisture freezes and tears the structure of the foam, after 3-5 years it turns into dust. XPS (extrusion) is the only standard for underground works.

3. the Warm Paving Technology: Shifting the Cold

It is not enough to insulate the foundation only vertically. The cold can pass "snuck" under the insulation. In order to block this effect, the technology of an insulated bridge is used.

How does this work:

- You lay the XPS sheets horizontally around the greenhouse under the soil layer or path.

- The width of such a strip should be equal to the frost depth in your region (usually 60-100 cm).

- Result: The ground underneath the footings does not freeze. The zero isotherm "moves away" from the greenhouse walls. The ground under the greenhouse retains the natural geothermal heat (+5...+7°C) that comes from the subsoil, even in severe frosts.

4. Frost Depth in Ukraine: Facts

According to building climatology, the estimated frost depth depends on the type of soil (clay freezes less, sand and rocky soil - deeper).

- Southern regions (Odessa, Nikolaev, Kherson): The normative depth is 0.8 to 0.9 meters.

- Center and Kiev: 1.0 to 1.1 meters.

- North and East (Kharkiv, Chernigov, Sumy): 1.1 to 1.3 meters.

Technical Solution: The foundation should be insulated to the full frost depth. If it is expensive and time-consuming to dig a trench of 1.2 meters, the use of "Warm Pavement" (see point 3) allows you to reduce the vertical depth of insulation to 40-60 cm, as you artificially raise the temperature of the ground around you.

5. Thermal break of beds (High beds)

Why is the advice to "raise the beds" not just about the comfort of your back, but about thermodynamics?

In a conventional greenhouse on the ground, the plant roots are in contact with the lower layers of soil. In winter, even with warm air, the soil temperature at floor level can be +5...+8°C. For most crops (tomatoes, cucumbers) at root temperature below +12...+14°C the assimilation of phosphorus and nitrogen stops. The plant "starves" in rich soil.

Bed-Thermos construction:

- The height of the box is 60-80 cm.

- The bottom of the bed is cut off from the parent soil with a layer of insulation (XPS) or an air gap is created (racks).

- Heating pipes (water circuit) or heating cable are laid inside the box.

- Benefit: You only heat a limited volume of fertile soil, not an endless mass of cold ground under the greenhouse. The efficiency of the heating system increases many times over.

Coverage: Selection of material with low U-value

The heat transfer coefficient (U-value, W/m²K) shows how much heat 1 square meter of flooring loses with a temperature difference of 1 degree. The lower the figure, the better.

Comparative table of materials (for conditions of Ukraine):

| Coating material | Thickness, mm | U-value (W/m²K) | Note |

|---|---|---|---|

| Glass (single) | 4 | ~6.0 | Catastrophic losses. Not for winter. |

| PE film (single) | 0.15-0.2 | ~6.5 | Doesn't keep the heat in, only out of the wind. |

| Polycarbonate (honeycomb) | 4 | 3.9 | Spring/Fall only. |

| Polycarbonate (honeycomb) | 10 | 2.9 | Minimum for winter. |

| Polycarbonate (honeycomb) | 16 (multi-chamber) | 2.0 – 2.3 | Optimal. |

| Supercharged double film | – | 3.0 – 3.5 | Industry Standard. |

| Double-glazed window (single-glazed) | 24 | ~2.5 | Expensive, hard, but effective. |

Solutions to minimize loss through coverage:

- Proper Polycarbonate: For a winter greenhouse, forget about the "four" (4 mm). Use polycarbonate with a minimum thickness of 10 mm, or better 16 mm with a multi-chamber structure (3-5 walls). The air in the chambers is the best insulator.

- Warning: When installing thick polycarbonate, be sure to use thermal washers and special profiles to avoid cold bridges through the screws.

- Supercharged Double Film System: This is a professional solution from industrial greenhouses. Two layers of film are attached to the frame and air is pumped between them with a small pump.

- Effect: An air cushion 15-30 cm thick is formed.

- Result: Heat losses are reduced by 30-40% compared to single foil. The structure becomes rigid and better resists snow loads (relevant for II-IV snow regions of Ukraine).

- Second Circuit ("Greenhouse in Greenhouse"): If you already have a greenhouse made of glass or thin polycarbonate, the fastest way to insulate is to stretch inside the second layer of film (better air-bubble) with a gap of 5-10 cm from the main cover.

Sealing: Combating infiltration

Even the warmest polycarbonate will not save if the greenhouse "walks in the wind". Warm air, rising up, creates excess pressure and tends to escape through the smallest gaps in the roof, sucking cold air from below.

- Sealers:

- Replace cheap foam tapes with quality EPDM (ethylene propylene rubber) sealants. They do not stick in the cold and last 15+ years.

- Glue all joints of polycarbonate, places of adhesion to the foundation, door and fore-openings.

- Tambour (Gateway): Entering your winter greenhouse directly from the street is a huge amount of heat loss every time you open the door.

- Solution: Be sure to add a vestibule (cold or warm) of at least 1x1 meter. It works as an airlock. Store equipment and water tanks there.

- Alternative: Entrance to the greenhouse directly from the house or heated outbuilding.

Thermal Shielding: Night Blanket

In winter, the night lasts up to 14-16 hours. At this time photosynthesis does not take place, light is not needed, but heat losses are maximum.

Technology: Installation of horizontal or pitched heat shields (curtains).

- Material: Special aluminized fabrics or non-woven fabrics (e.g. high density spunbond 60-100 g/m²).

- Principle: The screen reflects IR radiation back into the greenhouse and cuts off the "extra" volume of air under the roof ridge, which does not need to be heated at night.

- Efficiency: Heat savings of up to 30-50% at night.

- Implementation: You can use electrically operated automatic systems or a simple rope system for manual drapes.

North wall and reflectors

In Ukraine, the sun in winter moves in a low arc in the south. The northern side of the greenhouse receives almost no direct light, but actively loses heat.

- Insulating the north: Make the north wall opaque and insulated. You can cover it from inside with polystyrene foam or use sandwich panels during construction.

- Light Reflection: Cover the insulated north wall with foil material (foamed-in-foil). This will bring heat radiation back inside and increase plant light by reflecting sunlight.

Thermal storage: Passive energy

The use of inertial heat storage helps to smooth out diurnal temperature fluctuations by taking in excess heat during the day and giving it away at night.

- Water Batteries: The easiest and most effective way.

- Implementation: Barrels with water (better painted black), plastic water hoses laid in the inter-row or under racks.

- Physics: Water has a huge heat capacity (4.18 kJ/(kg-K)). Cooling down by 1 degree, 1 cubic meter of water gives off as much heat as 3000 cubic meters of air.

- Stone Accumulators: Concrete walkways, brick wall (Tromba) on the north side.

How to minimize heat loss in the greenhouse in winter: A comprehensive approach

Foundation insulation is the base, but heat escapes not only through the floor. To create a full-fledged winter greenhouse ("greenhouse-thermos"), it is necessary to close all energy leakage channels.

Where does the heat go? (Structure of heat loss)

| Loss channel | Share of total losses | Technical solution |

|---|---|---|

| Roof and walls | 60-70% | Multi-chamber polycarbonate (16+ mm) |

| Infiltration (Slits) | 15-20% | Sealing of joints, vestibule |

| Soil (Foundation) | 10-15% (without insulation - up to 40%) | XPS, warm paving |

| IR radiation at night | Significantly (cooling) | Heat shields |

Detailed component analysis

А. Coverage: Why 4 mm "doesn't work" in winter

The thickness of the polycarbonate determines not only its strength but also its thermal resistance (R-value). Normal summer polycarbonate (4 mm) holds heat only slightly better than glass. For winter use, chambering - the number of air layers inside the sheet - is critical.

- Polycarbonate 4-6 mm: 1 camera. Suitable for spring-autumn season. Freezes in winter.

- Polycarbonate 16 mm: Multi-chamber structure (3-5 chambers) + reinforced diagonal partitions. Air in the chambers is the best insulator. Heat losses are reduced by 2.5-3 times compared to thin sheet.

Б. Airtightness and Tambour

The quickest way to freeze a greenhouse is to open the door in the cold. Cold air is heavier than warm air, it instantly "flows" inside along the bottom, hitting the plants.

- Tambour: An airlock system (two doors) is mandatory. It creates a buffer zone where cold air is mixed without directly entering the growing area.

- Sealers: The use of EPDM-rubber (as in cars) instead of cheap plastic guarantees elasticity even at -20°C, preventing draughts.

В. Heat shields (Night mode)

At night, the greenhouse loses heat through radiation into the cold sky. A heat shield (a curtain made of a special fabric with aluminum threads) is rolled up under the ceiling at night.

- Effect: The screen reflects infrared heat back into the greenhouse.

- Savings: Reduces heating costs at night by 30-50%.

Partner selection: Engineering competence

The construction of a winter greenhouse is an investment project. An error in calculating snow load or polycarbonate thickness can lead to the destruction of the structure or the inability to maintain temperature.

NovaTeplica (Ukraine) specializes in industrial and farming solutions adapted to the climatic zones of Ukraine (snow loads up to 180 kg/m², wind loads up to 50 m/s).

- Design: Calculation of the frame taking into account the weight of the equipment (lamps, heating).

- Materials: Using certified polycarbonate (UV protection, 10+ years warranty).

- Experience: Realization of turnkey projects with integration of heating and ventilation systems.

Contact a professional to calculate the thermal balance of your future greenhouse so that your investment pays off in yields rather than going down the drain.